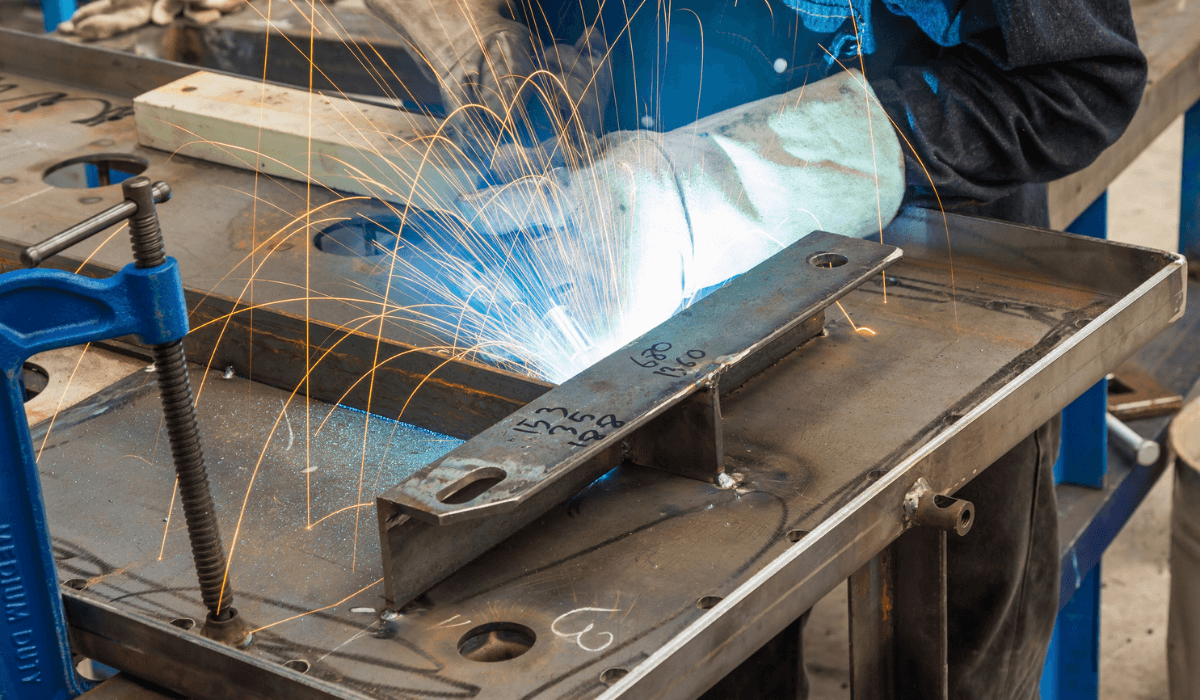

Welding is an integral part of manufacturing, especially in the automobile industry. The components of a vehicle need to withstand a significant amount of wear and tear over the course of a vehicle’s lifetime. The process utilizes heat and pressure to provide a consistent, durable component.

Read

Vietnam Precision Industrial Joint Stock Company

Address: Lot VIII-1, Honai Industrial Zone, Trangbom District, Dongnai Province, 810000 Vietnam.

Telephone: +84-251.3984.708

Address: Lot VIII-1, Honai Industrial Zone, Trangbom District, Dongnai Province, 810000 Vietnam.

Telephone: +84-251.3984.708